-

Acoustic Wood Panels

-

Acoustic Wood Slat Panels

-

Perforated Acoustic Wood Panels

-

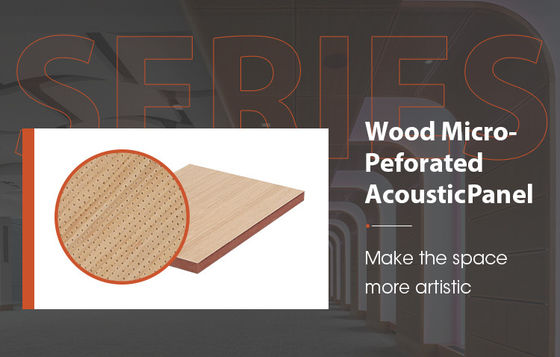

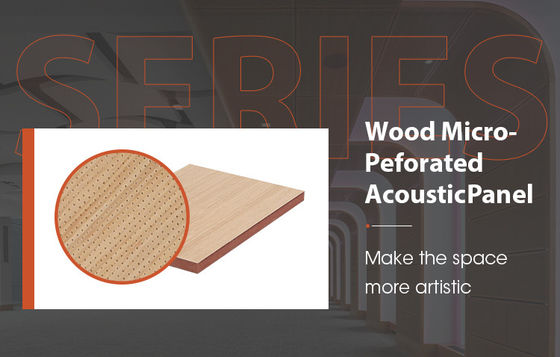

Micro Perforated Acoustic Panels

-

Grooved Acoustic Panels

-

Art Acoustic Panels

-

Acoustic Wood Ceiling Panels

-

3D Decorative Wall Panels

-

Laminate Wall Panels

-

Fabric Acoustic Panels

-

Wood Acoustic Diffuser Panels

-

Polyester Acoustic Panels

-

Sound Proof Mat

-

Acoustic Booth

-

Acoustic Wood Wool Panels

Super Micro Perforated Acoustic Panels MDF Board Noise Reduction 0.8 NRC

| Place of Origin | China |

|---|---|

| Brand Name | Winego |

| Certification | ISO9001 / FSC / Sound absorption coefficient Test Report |

| Model Number | PAV2.2-0.7 |

| Minimum Order Quantity | 200 sqm |

| Price | USD19.99-30.99 PER SQM |

| Packaging Details | Carton packing at 122*122*8cm per carton or other |

| Delivery Time | 21 days |

| Payment Terms | T/T, Western Union, MoneyGram |

| Supply Ability | 100000 Square Meter/Square Meters per month |

| Type | Micro Perforated Acoustic Panel | Size | 600/1200*600/1200/2400mm |

|---|---|---|---|

| Thickness | 12/15/18mm Or Other | Base Material | Standard E1 MDF/ECO MDF/FR MDF/HDF |

| Finish | Veneer/HPL/Melamine | Back | Fleece/Black Fabric/Black Sound Absorbing Fleece/Fiberglass Felt |

| Function | Sound Absorption And Noise Reduction | NRC | 0.8 |

| Highlight | mdf super micro perforated acoustic panels,micro perforated acoustic mdf board,noise reduction micro perforated acoustic panels |

||

Super Micro Perforated MDF Panels Sound Absorption and Noise Reduction

Description:

WINEGO Super Micro Perforated Sound Absorption and Noise Reduction Acousitic Panel are an effective sound-absorbing decorative material that improves the indoor acoustic environment by absorbing and dispersing sound through a microporous structure. Its beautiful, practical and environmentally friendly material features make it a common sound-absorbing product in interior decoration.Our products combine acoustic performance with aesthetic appeal, making them ideal for builders looking for reliable and attractive solutions.

Feature:

A variety of materials according to acoustic principles, reasonable cooperation, with excellent noise reduction and sound absorption performance, the mid and high-frequency sound-absorbing effect is particularly good.

Both natural wood texture, simple and natural; also reflect the modern rhythm of bright and bright style, the product is excellent decorative, can be decorated with natural wood grain, patterns and other decorative effects, provide a good visual enjoyment.

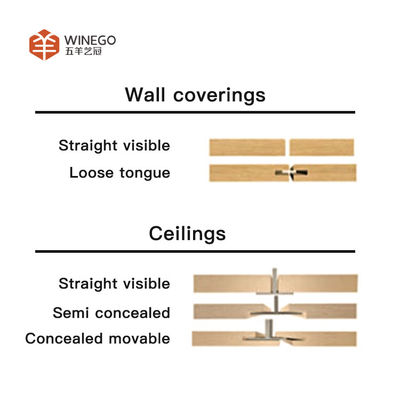

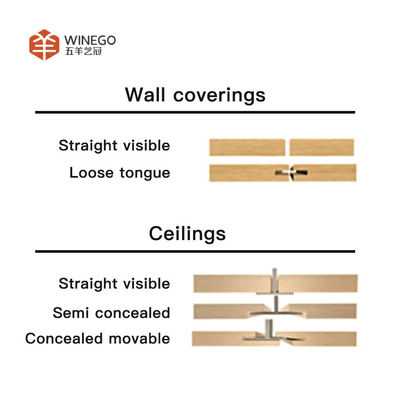

Installation options

Our microperforated acoustic panels can be manufactured in several versions, to be installed on walls or ceilings. In both cases you should leave behind a space as rear cavity filled with a low density mineral fibre glass wool panel to help improve the optimal absorption coefficient.

Specificatins:

| Name | Micro Perforated Acouostic Panels |

| Base Materials | MDF/FR MDF/HDF |

| Finish | Veneer/Melamine/HPL fire-proof |

| Model | PAV2.2/0.5 |

| Size | W 600/1200*L 600/1200/2400*T 15/18mm |

| Environmental protection | E1 or E0 |

| Warranty | 2years |

| Installation | Keel /Wooden batten |

| MIN. order quantity | 200 SQM |

| Packing details |

W1200mm*L1200mm*T 15mm: 4 pieces per pack,the size of the single package is W1225mm*L1225mm*T100mm,48.8kg per pack. LOGO service for big order |

| Delivery time | 3 weeks |

| Original place | Guangzhou,China |

| Payment term |

TT :50% deposit Balance before shipment |

| Additional service | OEM |

| NRC | 0.8 |

| Certificate | CE,FSC,France A+,ASTM-E84 1,BS476 PART7 |

| Brand | Winego |

Application:

Multi-functional hall

Conference room

Lectural hall

Opera house

Concert hall

Home theater

![]()

Install method:

WALL INSTALLATION

Method :Wood battens installation system

Step 1:Fix the wood battens to level the wall(spacing at 400-600mm).

Step 2:Fill in fiberglass acoustic wool between wood battens.

Step 3:Fix the perforated acoustic panel on the wood battens with gun nails,and insert the wooden slat into the side groove.

Step 4:Repeat until the installation is completed, the joints between the panels are generally recommended to be 3-5mm, and the nailing position is on the side of the panel.

Step 5:Installation completion effect.

![]()