-

Acoustic Wood Panels

-

Acoustic Wood Slat Panels

-

Perforated Acoustic Wood Panels

-

Micro Perforated Acoustic Panels

-

Grooved Acoustic Panels

-

Art Acoustic Panels

-

Acoustic Wood Ceiling Panels

-

3D Decorative Wall Panels

-

Laminate Wall Panels

-

Fabric Acoustic Panels

-

Wood Acoustic Diffuser Panels

-

Polyester Acoustic Panels

-

Sound Proof Mat

-

Acoustic Booth

-

Acoustic Wood Wool Panels

Micro Perforated Acoustic Wood Wall Panels Sound Barrier Sheets 1200X600 2400x1200mm

| Place of Origin | China |

|---|---|

| Brand Name | Winego |

| Certification | ISO9001 / FSC / Sound absorption coefficient Test Report |

| Model Number | E8-01 |

| Minimum Order Quantity | 200 sqm |

| Price | USD19.99-30.99 PER SQM |

| Packaging Details | Carton packing at 122*122*8cm per carton or other |

| Delivery Time | 21 days |

| Payment Terms | T/T, Western Union, MoneyGram |

| Supply Ability | 100000 Square Meter/Square Meters per month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Type | Micro Perforated Acoustic Panel | Size | 600/1200*600/1200/2400mm |

|---|---|---|---|

| Thickness | 12/15/18mm Or Other | Base Material | Standard E1 MDF/ECO MDF/FR MDF/HDF |

| Finish | Veneer/HPL/Melamine | Back | Fleece/Black Fabric/Black Sound Absorbing Fleece/Fiberglass Felt |

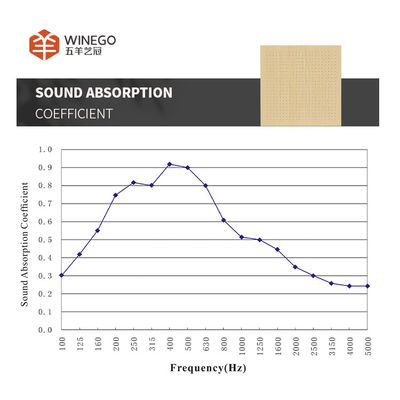

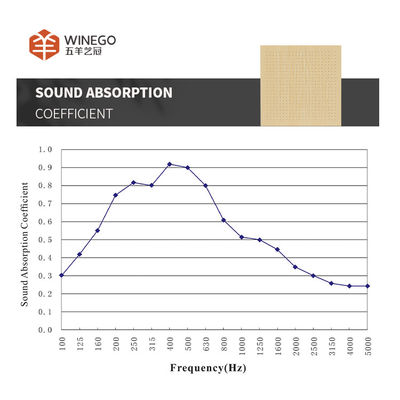

| Function | Sound Absorption And Decorative | NRC | 0.65 |

| Highlight | 1200x600 micro perforated wall panels,micro perforated sound barrier sheet,2400x1200mm micro perforated wall panels |

||

Micro Perforated Acoustic Wood Wall Paneling Sheets Sound Absorption

Description:

WINEGO Interior Microperforated Wood Sound Absorption Acoustic Panel are an effective interior sound-absorbing and decorative panels that improves the indoor acoustic environment by absorbing and dispersing sound through the microporous structure. Winego offers high-quality, eco-friendly, and fire-resistant panels. Our products combine superior acoustic performance with aesthetic flexibility, making them ideal for architects seeking both functionality and design.

Feature:

Effective Sound Absorption : Our micro perforated acoustic panels deliver exceptional sound absorption with an NRC of 0.8. This makes them highly effective at managing noise levels and improving sound clarity in various environments, creating a more comfortable acoustic experience.

The advantages of Winego micro perforated acoustic panels mainly include light material, no deformation, high strength, beautiful shape, elegant color, good decorative effect, strong sense of three-dimensional,

Easy to assemble, excellent noise reduction and sound absorption performance, as well as good sound absorption effect on medium and high frequency sound.

Installation options

Our microperforated acoustic panels can be manufactured in several versions, to be installed on walls or ceilings. In both cases you should leave behind a space as rear cavity filled with a low density mineral fibre glass wool panel to help improve the optimal absorption coefficient.

Specificatins:

| Name | Micro Perforated Acoustic Panels |

| Base Materials | MDF/FR MDF/HDF |

| Finish | Veneer/Melamine/HPL fire-proof |

| Model | E8-1 |

| Size | W 600/1200*L 600/1200/2400*T 15/18mm |

| Environmental protection | E1 or E0 |

| Warranty | 2years |

| Installation | Keel /Wooden batten |

| MIN. order quantity | 200 SQM |

| Packing details |

W1200mm*L1200mm*T 15mm: 4 pieces per pack,the size of the single package is W1225mm*L1225mm*T100mm,48.8kg per pack. LOGO service for big order |

| Delivery time | 3 weeks |

| Original place | Guangzhou,China |

| Payment term |

TT :50% deposit Balance before shipment |

| Additional service | OEM |

| NRC | 0.65 |

| Certificate | CE,FSC,France A+,ASTM-E84 1,BS476 PART7 |

| Brand | Winego |

![]()

![]()

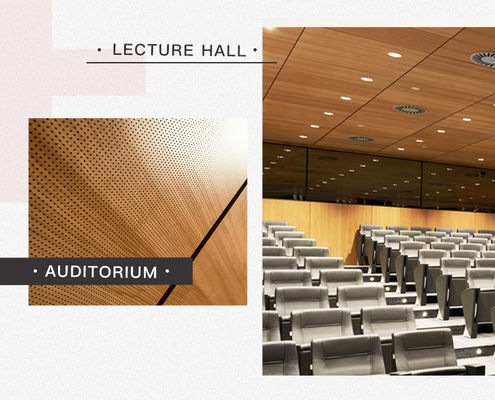

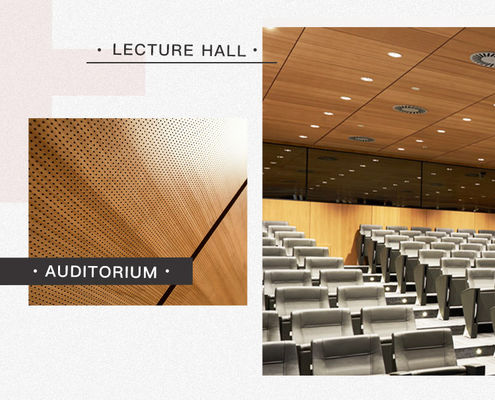

Application:

Multi-functional hall

Conference room

Lectural hall

Opera house

Concert hall

Home theater

![]()

Install method:

WALL INSTALLATION

Method :Wood battens installation system

Step 1:Fix the wood battens to level the wall(spacing at 400-600mm).

Step 2:Fill in fiberglass acoustic wool between wood battens.

Step 3:Fix the perforated acoustic panel on the wood battens with gun nails,and insert the wooden slat into the side groove.

Step 4:Repeat until the installation is completed, the joints between the panels are generally recommended to be 3-5mm, and the nailing position is on the side of the panel.

Step 5:Installation completion effect.

![]()