-

Acoustic Wood Panels

-

Acoustic Wood Slat Panels

-

Perforated Acoustic Wood Panels

-

Micro Perforated Acoustic Panels

-

Grooved Acoustic Panels

-

Art Acoustic Panels

-

Acoustic Wood Ceiling Panels

-

3D Decorative Wall Panels

-

Laminate Wall Panels

-

Fabric Acoustic Panels

-

Wood Acoustic Diffuser Panels

-

Polyester Acoustic Panels

-

Sound Proof Mat

-

Acoustic Booth

-

Acoustic Wood Wool Panels

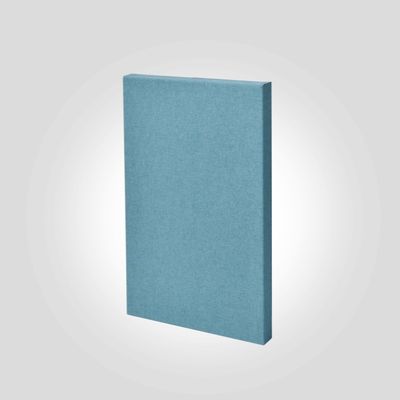

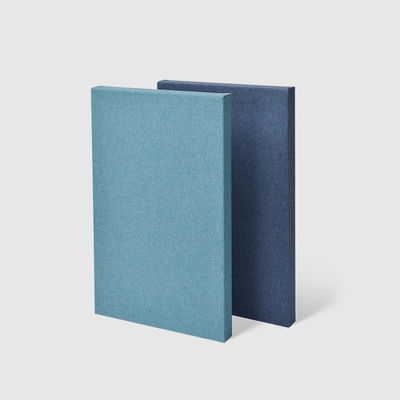

Formaldehyde Free Fabric Acoustic Panels Sound Proof Fabric Wrapped Wall Panels 32mm

| Place of Origin | Guangzhou,china |

|---|---|

| Brand Name | WINEGO |

| Certification | CE,FSC,France A+,ASTM-E84,BS476 part 7 |

| Model Number | FA32E |

| Minimum Order Quantity | 50 PCS |

| Packaging Details | Different sizes at different qty, LOGO service for big order |

| Delivery Time | 2 weeks |

| Payment Terms | TT :50% deposit Balance before shipment |

| Supply Ability | 1000sqm per week |

| Finish | Flame-retardant Acoustic Cloth/Class A Fire Resistant Glass Fiber Cloth | Frame | Eco Glue Resin Frame/Customized High-strength Alloy Frame |

|---|---|---|---|

| Model | FA32E | Minimum Order Quantity | 50 |

| Base Material | White Eco-friendly Acoustic Wool | Edge | Bevel(default), Right Angle |

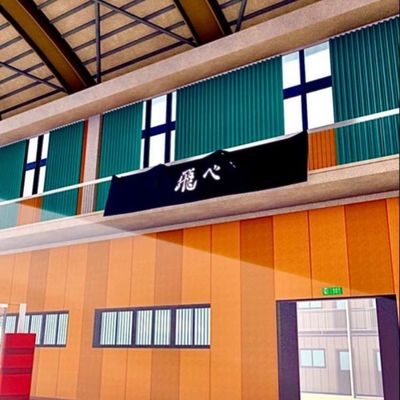

| Application | Offices, Studios, Home Theaters | Installation Methods | Nail-free Glue Fixed/ Clip Hanging Installation |

| Highlight | formaldehyde free fabric acoustic panels,sound proof fabric wrapped panels,32mm soundproof fabric panels |

||

Eco-friendly Formaldehyde-Free Fabric Acoustic Panels with Sound Proof

Description:

Formaldehyde-free fabric acoustic panel with high-density white eco-friendly acoustic wool be wrapped, which in structure, healthy, safe and friendly to human body. Typical porous sound-absorbing material, full-frequency sound absorption, can absorb a large amount of sound energy in the room, reduce reverberation time and indoor noise as fixed as well panel, ceiling panel, etc.

Built-in 32mm white eco-friendly acoustic wool, which has zero formaldehyde and no dust, is healthy, safe, friendly to human body, strong hydrophobicity and longer service life.

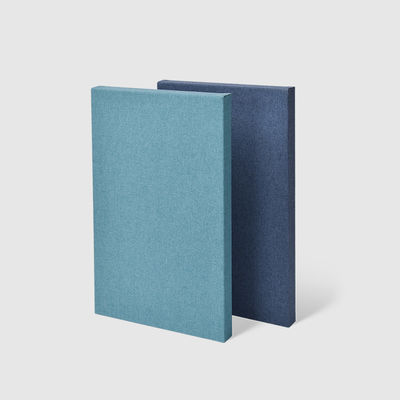

Flame -retardant acoustic cloth, class A fire resistant glass fiber cloth, etc as options, with various categories, colors and patterns, and also accept customized cloth; Customized eco glue resin frame and high-strength alloy frame, with better performance at fireproof, environmental protection, moisture-proof and deformation resistance.

Feature:

Advanced Sound Absorption (NRC: 0.9)

Edges can be finished in square, small bevel, or large bevel designs.

The substrate is durable, impact-resistant, and offers excellent tackiness.

Features strong water resistance and a longer service life.

Made from Class A fire-resistant materials.

Customizable with a high-strength alloy frame.

Offered in a range of sizes and colors.

Exceptional durability.

Outstanding construction quality.

Specifications:

| NAME | FORMALDEHYDE-FREE FABRIC ACOUSTIC PANEL |

| FINISH | Flame-retardant acoustic cloth/Class a fire resistant glass fiber cloth |

| BASE MATERIALS | White Eco-friendly Acoustic Wool |

| FRAME | Eco glue resin frame/customized high-strength alloy frame |

| MODEL | FA32E |

| Size |

W600mm*L600/1200/2400mm*T32mm |

| Environmental Protection | E0 |

| Warranty | 2 years |

| INSTALL | Nail-free glue,High-strength alloy frame with clip hanging,Vertical hanging with adjustable suspension hook and helical spring clip |

| MIN.ORDER | 50 PCS |

| PACKAGE DETAILS |

Different sizes at different qty, |

| Delivery Time | 2 weeks |

| Original Place | Guangzhou,china |

| Payment Term |

TT :50% deposit |

| Additional Service | OEM |

| NRC | 0.9 |

| Certificate | CE,FSC,France A+,ASTM-E84,BS476 part 7 |

| Brand | WINEGO |

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

FAQ:

Q5. How to control the quality in your factory?

A: We have taken a series of strict measures to ensure that every product produced by the factory meets high standards. Firstly, we have dedicated quality inspectors responsible for supervising every step of the production process, from raw material procurement to production manufacturing, to final product packaging and shipment. Secondly, we have implemented strict quality inspection standards to ensure that our products undergo multiple rigorous inspections on the production line and before leaving the factory, to ensure their stable and reliable quality. In addition, we also regularly maintain and update equipment to ensure the normal operation of production facilities and the continuous improvement of product quality.

Q6:How do I clean fabric acoustic panels?

A:Fabric acoustic panels can be cleaned with a vacuum cleaner or a soft brush to remove dust and debris. For stubborn stains, mild soap and water can be used, but it's essential to avoid excessive moisture to prevent damage to the panels.