-

Acoustic Wood Panels

-

Acoustic Wood Slat Panels

-

Perforated Acoustic Wood Panels

-

Micro Perforated Acoustic Panels

-

Grooved Acoustic Panels

-

Art Acoustic Panels

-

Acoustic Wood Ceiling Panels

-

3D Decorative Wall Panels

-

Laminate Wall Panels

-

Fabric Acoustic Panels

-

Wood Acoustic Diffuser Panels

-

Polyester Acoustic Panels

-

Sound Proof Mat

-

Acoustic Booth

-

Acoustic Wood Wool Panels

Micro-perforated Acoustic Panel Elegant Solution for Noise Reduction

| Place of Origin | Guangzhou,china |

|---|---|

| Brand Name | WINEGO |

| Certification | CE,FSC,France A+ |

| Model Number | PAV2.2/0.5-12/15 |

| Minimum Order Quantity | 100 SQM |

| Packaging Details | W230m*L2430mm*T130mm,27.75kg per pack.LOGO service for big order |

| Delivery Time | 2 weeks |

| Payment Terms | TT :50% deposit Balance before shipment |

| Supply Ability | 10000sqm per week |

| Sound Absorption | 0.8 NRC | Material | MDF |

|---|---|---|---|

| Size | W600/1200*L600/1200/2400*T15/18mm | Finish | Veneer/Melamine/HPL Fire-proof/PU Paint |

| Type | Acoustic Panel | Packing | Carton |

| Acoustic Performance | Highly Effective | Application | Auditorium, Conference Room, Recording Studio, Home Theater |

| Highlight | Elegant Solution Micro-perforated Acoustic Panel,Noise Reduction Micro-perforated Acoustic Panel,Micro-perforated Acoustic Panel |

||

Micro-perforated Acoustic Panel Elegant Solution for Noise Reduction

Description:

The micro-perforated acoustic panel offers a high-performance acoustic solution that merges practicality with stylish aesthetics. Featuring front-facing micro holes (0.4 to 1mm) and rear perforations, it functions as a Helmholtz resonance system, effectively reducing noise in medium to low frequencies. Constructed from durable high-density board, it comes in a range of finishes to meet different design requirements. Ideal for applications in both residential and commercial spaces, this panel creates a calm and visually appealing environment. Its eco-conscious design and fire-resistant properties make it particularly suitable for contemporary sustainable projects. Whether enhancing a cozy home atmosphere or refining acoustics in a dynamic office, this panel ensures top-notch sound control and aesthetic harmony.

Feature:

Effective Sound Absorption: Helmholtz resonance system for superior noise control.

Elegant Finishes: Multiple options to enhance any decor.

Eco-Friendly: Safe and sustainable materials.

Durable Construction: Built to withstand physical impact.

Versatile Application: Suitable for walls and ceilings.

Specifications:

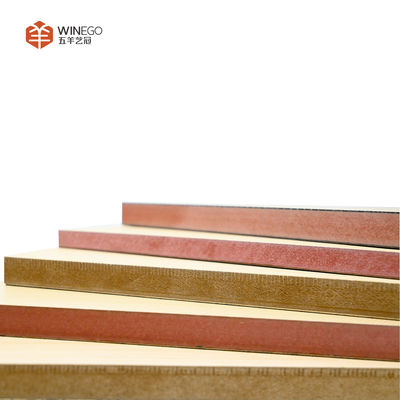

| NAME | Super Micro-Perforated Acoustic Panel |

| FINISH | Veneer/Melamine/HPL fire-proof |

| BASE MATERIALS | MDF/A grade MGO/Solid wood |

| MODEL |

PAV2.2/0.5-12/15 |

| Size |

W590/1200*L590/1200/2420*T15/18mm |

| environmental protection | E1 |

| warranty | 2 years |

| INSTALL | Keel/Nail gun |

| MIN.ORDER | 100 SQM |

| PACKAGE DETAILS |

W200mm*L2400mm*T 15mm: 6 pieces per pack,the size of the single package is W230m*L2430mm*T130mm,27.75kg per pack. W1200mm*L1200mm*T 15mm: 4 pieces per pack,the size of the single package is W1225mm*L1225mm*T100mm,48.8kg per pack. LOGO service for big order |

| Delivery time | 2 weeks |

| Original place | Guangzhou,china |

| Payment term |

TT :50% deposit |

| Additional service | OEM |

| NRC | 0.8 |

| Certificate | CE,FSC,France A+ |

| Brand | WINEGO |

| Project Solution Capability | Project Design,3D model design,Graphic design,Material Production,Shipping and Deliver |

| Design Style | Modern |

| After-sale Service | Online technical support,Return and Replacement,Installation Instruction |

![]()

![]()

![]()

![]()

![]()

![]()

Wall Installation Process:

Wood Batten Wall System Installation

Step 1: Install the wood battens securely on the wall, ensuring they are perfectly level. The spacing between battens should be maintained between 400-600mm.

Step 2: Fill the gaps between the battens with fiberglass acoustic wool to improve soundproofing.

Step 3: Fix the perforated acoustic panels onto the battens using a nail gun and insert the wooden slats into the grooves along the sides.

Step 4: Continue with the installation while leaving a 3-5mm gap between adjacent panels. Nail placement should be along the edges.

Step 5: Inspect the installation to ensure stability and proper alignment.

Suspended Ceiling System Installation Options

Method A: Exposed Ceiling SC-E

-

Mount the L-hanger on the suspension rod and fix the T-type main tee. Clip the cross tee in place and secure the corners.

-

Proceed with the exposed ceiling installation.

-

Inspect and finalize the ceiling installation.

Method B: Tegular Ceiling SC-T

-

Attach the L-hanger to the suspension rod, secure the T-type main tee, and insert the cross tee, ensuring the corners are locked.

-

Fit the tegular ceiling panels into position.

-

Complete and review the installation.

Method C: Concealed Ceiling SC-C

-

Fix the L-hanger with suspension rods, install the main tee, and clip the cross tee securely in place while reinforcing the corners.

-

Carefully place the concealed ceiling panels.

-

Finish and inspect the final result.