-

Acoustic Wood Panels

-

Acoustic Wood Slat Panels

-

Perforated Acoustic Wood Panels

-

Micro Perforated Acoustic Panels

-

Grooved Acoustic Panels

-

Art Acoustic Panels

-

Acoustic Wood Ceiling Panels

-

3D Decorative Wall Panels

-

Laminate Wall Panels

-

Fabric Acoustic Panels

-

Wood Acoustic Diffuser Panels

-

Polyester Acoustic Panels

-

Sound Proof Mat

-

Acoustic Booth

-

Acoustic Wood Wool Panels

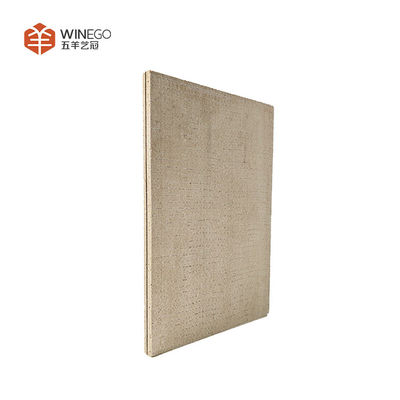

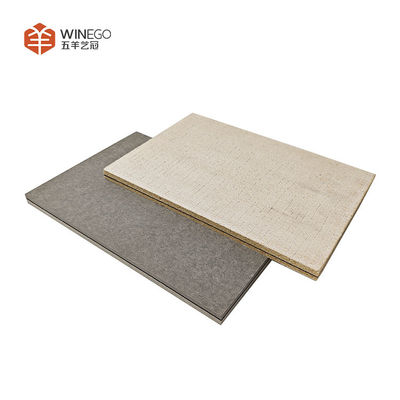

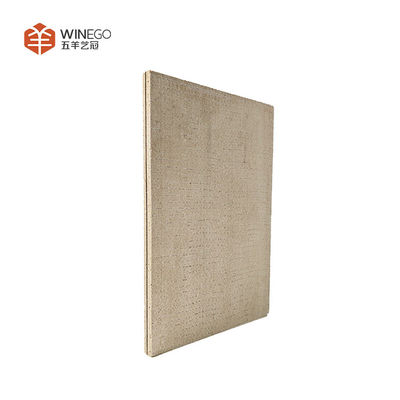

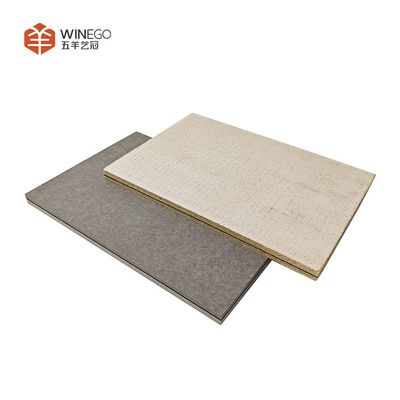

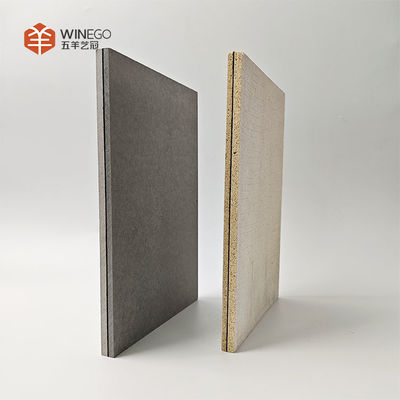

Eco-Friendly and Durable Sound Insulation Board For KTV Wall and Ceiling

| Features | Lightweight, Easy To Install, Durable | Size | W1220*H2440*T 16mm |

|---|---|---|---|

| Sound Insulation | 36dB/38dB | Eco Performance | Zero Formaldehyde Emission |

| Usage | Sound Absorption And Decoration | Per PC Weight | 55kg/ 61.5kg/61.5kg/69.5kg |

| Highlight | KTV Sound Insulation Board,Durable Sound Insulation Board,Eco-Friendly Sound Insulation Board |

||

Eco-Friendly and Durable Sound Insulation Board For KTV Wall and Ceiling

Description:

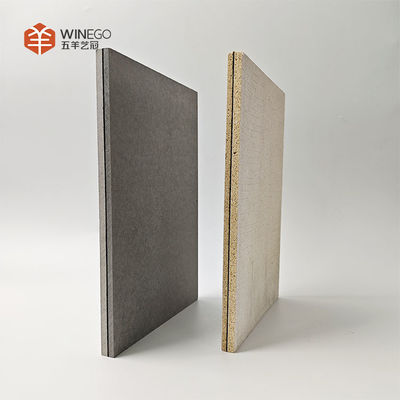

IB06 is a high-pressure composite three-in-one sandwich structure board, with gray MGO board and white MGO board at different densities and thicknesses on both sides, and polymer damping felt sandwiched between them to form damping constraint. The sound wave is transmitted in the solid through vibration, so the composite damping sound insulation board can effectively convert sound energy into heat energy; At the same time, the composite use of different sound insulation materials gives full play to the advantages of various sound insulation materials and improves the overall performance of sound insulation. This board multiple improves the air sound insulation and structural sound insulation of the original material.

IB07 is made of high-density inorganic materials with different thicknesses on both sides, with 2mm polymer damping felt in the middle, and is compounded into a three-in-one sandwich structure under high pressure. The two inorganic materials and the middle damping felt form damping constraints, which change the resonance frequency of the original material and multiply improve the air sound insulation and structural sound insulation of the original material.

IB07E is made of high-density inorganic materials with different thicknesses on both sides, with 2mm polymer odor-purifying and environment-friendly damping layer sandwiched in the middle, and is compounded into a three-in-one sandwich structure under high pressure. The two inorganic materials and the middle damping felt form damping constraint, which changes the resonance frequency of the original material, effectively improves the air sound insulation and structure sound insulation of the original material, and is used in places with very high requirements for environment-friendly odor.

IB08 is composite of inorganic materials with different materials, thicknesses and densities on both sides, with 2mm polymer damping glue in the middle, and is composite into a three-in-one sandwich structure under high pressure. Two inorganic materials with higher density form damping constraint with the middle damping glue, which changes the resonance frequency of the original material and highly increases the air sound insulation and structural sound insulation of the original material.

Specificatins:

| Name | Sound Insulation Board |

| Sound Insulation | 36dB/ 38dB |

| Size |

W1220*L2440*T16mm |

| Model | IB06/IB07/IB07E/IB08 |

| Environmental protection | E1 |

| Warranty | 2years |

| Installation | Screw/ Nail gun |

| MIN. order quantity | 20PCS |

| Fire performance |

GB 8624 B1(B-s1, d0)

|

| Delivery time | 3 weeks |

| Original place | Guangzhou,China |

| Payment term |

TT :50% deposit Balance before shipment |

| Additional service | OEM |

| Certificate | CE,FSC,France A+ |

| Brand | Winego |

Sound Insulation Board Installation Methods:

1.Cut with the stone saw and the electric cutting machine. Grind the fracture surface to ensure the joint effect.

2.Punch directly with the electric drill or the tapper. The hole diameter should be proper to prevent expanding sound leakage.

3.After cutting and punching, please clean up the powdery dust may rise on the surface.

4.After filling the acoustic damping sealing glue SG-1 , fix and Install the sound insulation board with the flat Head self tapping screws.

Application:

1.Equipment machinery room

2.Office

3.KTV

4.Nightclubs

5.Leisure clubs

6.Gymnasiums and other places that need to improve the sound insulation of walls and ceilings

7.Houses

8.Hotel rooms

9.Private cinemas

10.HiFi rooms

11.Piano practice rooms

12.Recording rooms and other places that need to improve the sound insulation of walls and ceilings

![]()